The Basics of Hydraulic Cylinder Parts and Functions

Hydraulic cylinders are super important for lots of machines. They turn liquid power into strong pushes or pulls. You see them in stuff like bulldozers, cranes, and farm tractors. They make things move straight and strong.

Key Components of Hydraulic Cylinders

Hydraulic cylinder parts and functions work together like a team. Here’s what’s inside:

Cylindrical Barrel: This is the main tube. It holds the liquid and lets the piston slide inside.

Piston: This part splits the tube into two sides. It moves when liquid pushes it, making the action happen.

Piston Rod: It’s stuck to the piston. It carries the push to whatever you’re moving.

Seals: These stop liquid from leaking out. They keep the pressure tight.

End Caps: These close off the tube’s ends. They also help you bolt the cylinder to your machine.

Functions of Hydraulic Cylinder Parts in Various Applications

Every piece in a hydraulic cylinder has a job. Seals keep things tight so no liquid escapes. That makes the system work great. The piston rod’s gotta be tough for heavy jobs, like moving dirt in construction or lifting stuff in warehouses. These cylinders let excavators dig deep, cranes lift big loads, and tractors steer or lift with ease. They’re like the muscles of all kinds of machines.

The Impact of High Temperatures on Hydraulic Cylinders

Hot weather can mess up hydraulic cylinders big time. Knowing how heat hurts them helps keep your machines running good.

How Heat Affects Hydraulic Cylinder Performance

When it gets super hot, the liquid inside gets thinner. That’s bad for keeping parts slippery, so they rub too much. This wears stuff out faster and makes the system less strong. If temps go past 110–130°F, seals can get weak and start leaking. That lets dirt in, which is no good.

Potential Damage to Hydraulic Cylinder Parts and Functions in High-Temperature Environments

Too much heat can wreck things:

Seal Failure: Heat makes seals lose their toughness. They start leaking.

Liquid Gunk: Hot temps turn the liquid sludgy. That clogs up valves and pipes.

Metal Wear: Long heat makes rods and tubes weaker. Keeping things cool is key to avoid these headaches.

Tips for Mitigating High-Temperature Effects on Hydraulic Systems

To keep your system safe from heat:

Pick seals that can handle hot temps.

Add cooling gadgets, like heat exchangers.

Check often for leaks or clogs in cooling parts.

Use liquids made for hot places. Doing these keeps your hydraulic cylinder parts and functions working great, even in crazy heat.

The Impact of Low Temperatures on Hydraulic Cylinders

Cold weather’s tough on hydraulic systems too. It can slow things down or break stuff if you’re not careful.

Challenges Faced by Hydraulic Cylinders in Cold Environments

When it’s freezing, the liquid gets thick like syrup. That makes it hard for pumps to move it around. It puts extra stress on all the parts, which isn’t fun for your machine.

Effects of Low Temperatures on Hydraulic Cylinder Parts and Functions

Cold can cause these problems:

Thick Liquid: Gooey liquid slows everything down. It can even cause air bubbles that hurt the system.

Water Buildup: Cold air can make moisture inside, which rusts parts or clogs stuff.

Fragile Metal: Rods and other bits can snap easier in the cold. Plus, when things keep freezing and thawing, it wears out materials like aluminum or steel.

Strategies for Protecting Hydraulic Systems from Low-Temperature Conditions

To keep things running in the cold:

Use liquids made for chilly places. They stay runny.

Warm up the system with heaters before you start.

Check seals a lot. Swap them for cold-proof ones if they’re bad.

Keep machines inside when you’re not using them. It saves them from freezing.

Yantai Shining Hydraulic Technology CO.,LTD makes lightweight hydraulic cylinder manufacturers built for all kinds of weather.

Choosing the Best Hydraulic Cylinder in 2025 for Extreme Temperature Conditions

Factors to Consider When Selecting a Durable Hydraulic Cylinder

Picking the best hydraulic cylinder in 2025 for hot or cold places takes some thinking. The material’s super important. Cylinders gotta handle big pressure and tough jobs while staying strong. For hot spots, go for stuff like stainless steel or special alloys that don’t mind heat. In cold areas, pick metals like certain aluminums that won’t snap when it’s freezing.

Seals matter a ton too. Cold makes them stiff and leaky. Heat can wreck them. So, get seals made for crazy temps to keep things tight. The liquid you use is a big deal too. It’s gotta stay just right—not too thick or thin—no matter the weather. That stops bubbles or dry spots.

Don’t forget how the cylinder’s built. Ones with cooling or heating tricks baked in handle wild temps better. Also, lightweight hydraulic cylinder manufacturers are getting popular. They’re easier to fit in machines but still super tough.

Innovations in Lightweight Hydraulic Cylinder Manufacturers for Enhanced Temperature Resistance

Lightweight hydraulic cylinder manufacturers are doing cool new stuff. They use lighter materials, like composites, that are strong but not heavy. That’s great for things like planes or cars. Some even add smart sensors. These check temps and pressure while you work. They warn you if things get too hot or cold, so you can fix stuff before it breaks.

Yantai Shining Hydraulic Technology CO.,LTD builds awesome cylinders for tough weather. Their gear shows how new tricks keep machines running smooth, no matter what.

Maintenance Practices to Protect Hydraulic Cylinders from Extreme Temperatures

Regular Inspection and Maintenance of Hydraulic Cylinder Parts and Functions

Checking your cylinders often stops little problems from getting big. Look at seals for cracks or weird shapes. That keeps leaks away. Check the piston rod for scratches or dents too. It helps everything move nice and easy.

Clean the outside to stop dirt from sneaking in during fixes. Make sure the liquid’s clean too. Dirty liquid can gum up filters and valves, making things hot or slow. Swap out worn parts quick, like old seals for ones that can handle hot or cold. That keeps your hydraulic cylinder parts and functions happy.

Lubrication Techniques to Enhance Performance in Varying Temperatures

Good grease makes parts slide easy, so your cylinder lasts longer. In hot places, use heat-proof lubes that don’t get runny. In cold spots, pick ones that stay slippery even when it’s freezing. That keeps things moving smooth.

Warm-up gadgets are great for cold days. They heat the liquid before you start, so parts don’t strain. Cooling systems, like heat exchangers, pull extra heat out when it’s hot. Check lube levels often. Too little can hurt parts or make things overheat.

FAQ Section

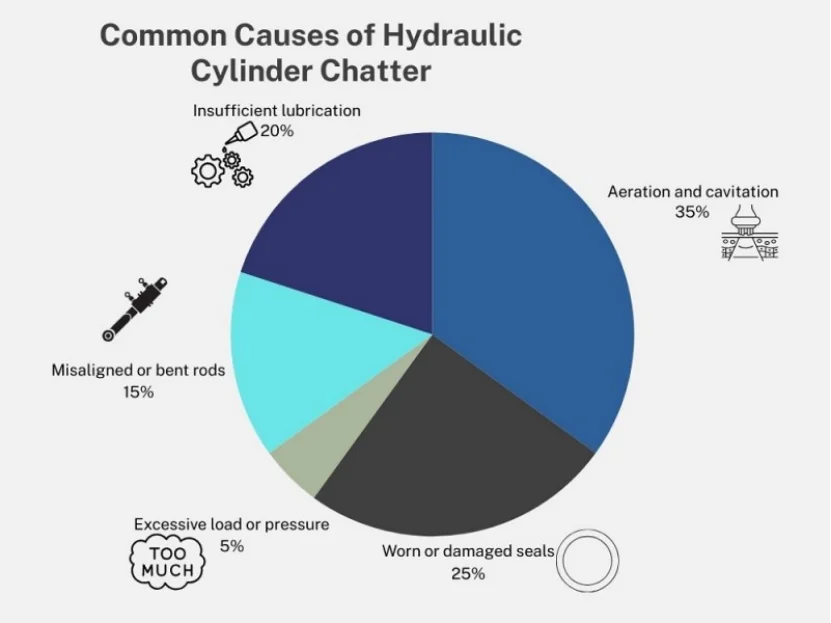

Q: What are the main causes of overheating in hydraulic systems?

Stuff like dirty liquid, air leaks, low liquid levels, clogged coolers, or bad flow controls can make things too hot.

Q: How do I prevent seal failure due to extreme temperatures?

Use seals built for hot or cold weather. Check them a lot for wear.

Q: Can low temperatures permanently damage my hydraulic cylinder parts and functions?

Yup, long cold spells can make metals weak, seals brittle, or cause rust from water buildup if you don’t protect them.

Q: What type of fluid should I use in extreme conditions?

Pick liquids made for hot or cold places. Ask your maker what’s best.

Q: How often should I inspect my best hydraulic cylinder in 2025?

Check as often as the maker says. Do it more if you’re in crazy hot or cold spots.

For custom fixes and pro tips on keeping your hydraulic systems running in any weather, hit up Yantai Shining Hydraulic Technology CO.,LTD! They’re in Yantai Economic Zone—China’s Shandong Free Trade Zone—and make top-notch gear with smart engineering.