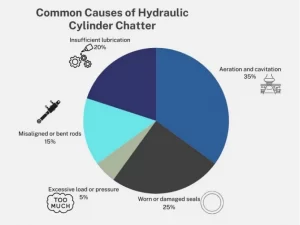

Common Reasons Behind Hydraulic Cylinder Chatter

Hydraulic cylinder chatter is characterized by a rapid, repetitive motion or vibration of the cylinder, which can cause noise and affect the smooth operation of the system. It is typically a symptom of underlying problems within the hydraulic system. Here are some common causes of hydraulic cylinder chatter:

Air Entrapment in the Hydraulic System

Air stuck in the hydraulic fluid is a big culprit. It squishes down and pops back up fast, making the cylinder jump around. This causes chatter. You might see bubbly oil, hear hissing sounds, or notice the cylinder moving unevenly. Those air bubbles act like little springs. They shrink when pressure hits and bounce back when it drops. That’s what makes the motion shaky.

Contaminated Hydraulic Oil and Its Effects

Dirty oil with bits of gunk or grime can cause trouble. It clogs things up and makes the flow uneven, leading to chatter. Bad filters or worn seals let dirt sneak in, which can block valves or scratch inner parts. Look for oil that’s cloudy, has specks in it, or looks sludgy. You might hear weird noises or see the system acting sluggish. Keep the oil clean by filtering it regularly and swapping it out as the maker suggests.

Worn or Damaged Seals Within the Cylinder

Seals are super important for keeping pressure steady. If they’re old or busted, they leak inside. This causes uneven pressure and jerky moves, which means chatter. Leaky seals can also let in dirt or air. Check for oil dripping near rod ends or gland spots. You might notice weaker lifting or odd cylinder movements. Seals wear out from age, bad setup, or super hot or cold conditions.

Improper or Worn Parts for Hydraulic Cylinder

Using the wrong or worn-out parts for hydraulic cylinder setups is a recipe for trouble. Parts that don’t fit right or are worn down cause uneven forces. This leads to chatter. Look at pistons, rods, bushings, and bearings for scratches, bends, or wear. Always pick parts that match the maker’s specs to keep things running smoothly.

Inadequate Hydraulic Oil Flow or Pressure Supply

If oil doesn’t flow well, the system gets out of whack. Clogged filters, squished hoses, or pumps that are too small can mess up pressure. This causes chatter. Use flow meters and pressure gauges to spot problems. Check for blocked filters, damaged hoses, or weak pumps. Fixing these keeps the oil flowing right.

Cavitation in the Hydraulic Circuit

Cavitation is when tiny vapor bubbles form in low-pressure areas. They pop hard when pressure spikes, causing chatter. This can chew up metal surfaces in pumps and cylinders. Listen for knocking sounds—that’s a big hint of cavitation. Check parts for rough, pitted spots. Those show cavitation damage.

Incorrect Cylinder Mounting and Alignment

If the cylinder isn’t set up right, it takes on uneven loads. This makes it chatter and wears out seals and rods faster. Loose or bent mounting brackets can cause this. When installing, use alignment tools to get everything lined up perfectly, following the equipment’s rules.

Diagnosing Hydraulic Cylinder Chatter

Identifying Audible and Visual Signs of Chatter

Chatter sounds like quick, clicking noises. You might feel shakes through the controls or see the cylinder move jerkily when it extends or retracts. Bubbly oil in the reservoir is a warning sign. It often means air is stuck in the system, causing chatter.

Evaluating System Pressure and Flow Conditions

Put pressure gauges at different spots in the system to check for ups and downs. Flow meters can find blockages from clogged filters or parts that are too small. Pressure should stay steady when the system’s working hard. Sudden drops might mean leaks or cavitation spots forming.

Inspecting Internal Components and Seals for Damage

Take the cylinder apart carefully. Look for worn-out seals or O-rings. Check piston rods for pitting or scratches. Peek inside the cylinder walls for scratches from dirt. Small damage might be fixed by rehoning. But if it’s really bad, you may need a new cylinder housing. Figuring out the main issue stops the problem from coming back after hydraulic cylinder repair.

Testing for Air in the Hydraulic Lines

Bleeding the system clears out trapped air. If air keeps getting in, check suction lines for leaks. Look at fittings, too. Make sure the reservoir has enough fluid. Also, check that return lines don’t cause turbulence, which can pull in air. Tight connections keep air out.

Effective Methods for Hydraulic Cylinder Repair

Fixing chatter means tackling the problem based on what you find. This could be swapping parts, cleaning fluid, or other steps.

Replacing Faulty Parts for Hydraulic Cylinder

Swap out worn pistons, rods, or bushings. Use parts for hydraulic cylinder that match the maker’s specs. This prevents misalignment that causes chatter. Yantai Shining Hydraulic Technology CO.,LTD has custom solutions, including high-quality parts for hydraulic cylinder systems. These are great for fields like farming and building.

Flushing and Replacing Contaminated Hydraulic Fluid

Use clean, top-notch hydraulic oil. Flush out old oil completely with the right cleaners before adding new oil. This stops dirt from mixing back in. Put in fresh filters after flushing. Old filters can hold onto gunk, which can hurt valves and other parts.

Bleeding Air from the System Properly

After adding new oil, move the actuators slowly through their full range a few times. Watch the reservoir levels. This pushes out air pockets. If bubbles keep showing up, check suction lines for leaks. Look at reservoir breather caps and pump shaft seals, too. These might let air sneak in during work.

Resealing or Rebuilding the Affected Cylinder

If seals are the problem, use rebuild kits with all the right gaskets. Don’t just replace one seal—using a full kit makes sure everything fits well. This lowers the chance of future leaks. Regular care keeps cylinders working longer. But if the barrel has cracks or big damage, replacing the whole cylinder is often better than fixing it again and again. For solid hydraulic cylinder repair, Yantai Shining Hydraulic Technology CO.,LTD offers custom replacements. These are tested tough with endurance tests to handle hard jobs (Customization Service available).

Frequently Asked Questions (FAQ)

What causes a clicking sound in my hydraulic cylinder?

Clicking usually comes from air trapped in the system. The air squishes and expands as pressure shifts, making quick pulses called chatter. Bleeding the lines often fixes this fast, as long as no leaks let air back in.

How do I know if my hydraulic oil is contaminated?

Check for dark, cloudy oil or sludge at the tank’s bottom. A strange smell or bits in the oil are clues, too. Dirty oil needs flushing and replacing right away to stop damage to valves, pumps, or cylinders.

Can worn seals really cause performance issues?

You bet! Worn seals let oil leak inside. This cuts power and lets in dirt or air, causing jumpy moves and chatter. Replacing bad seals is a big part of hydraulic cylinder repair.

Is cavitation dangerous?

Absolutely! Cavitation makes tiny bubbles that burst and damage metal surfaces in pumps, valves, or cylinders. Over time, this can wreck the system. Right pump sizing and fluid choices can stop it.

When should I replace instead of repairing my hydraulic cylinder?

Replace the cylinder if rods are too bent to fix, barrels have deep scratches or pitting, or seal grooves are warped. If repairs keep failing, a new unit with quality parts for hydraulic cylinder, like those from Shining Hydraulic, is often smarter.

To find out how Shining Hydraulic’s products, can stop chatter and make your equipment work better, get in touch today. Shining Hydraulic, located in Yantai Economic and Technological Development Zone in the Yantai Area of Shandong Free Trade Zone, is all about delivering smart, dependable solutions made just for you.