Current Landscape of the Hydraulic Cylinder Industry

Market Demand and Global Supply Chain Dynamics

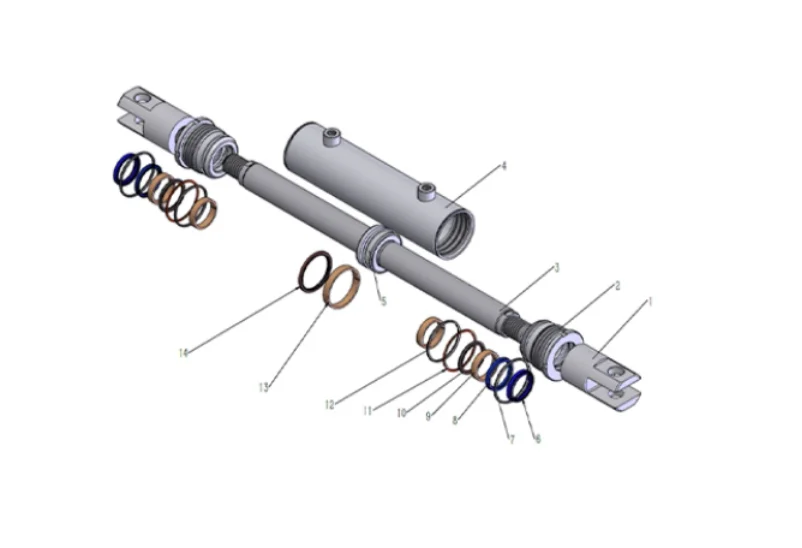

Hydraulic cylinders are vital parts in fields like construction, farming, mining, and factories. They turn liquid power into straight-line force, making them key for lifting, pushing, and pressing tasks. As machines worldwide get smarter, the need for strong hydraulic systems keeps growing. But, this rise faces hurdles. Supply chain issues, changing prices for raw materials, and a lack of workers make things tough.

Machines are getting more complex. This pushes companies to find special hydraulic cylinders that meet tough demands for top performance.

Key Challenges Faced by Hydraulic Cylinder Manufacturers

Makers of hydraulic cylinders deal with big problems. They must keep quality high while costs push them down. They need to deliver fast, even with global shipping delays. Clients also want custom designs to fit their needs. These cylinders must handle extreme heat or cold, heavy weights, and rough conditions while moving smoothly and accurately.

This calls for better materials and careful engineering. A common issue is cylinder failure from poor upkeep or bad design. Signs like odd noises, too much heat, or slow motion can point to leaks inside or cavitation. Both hurt how well the system works.

Role of a Hydraulic Cylinder Supplier in Today’s Market

A hydraulic cylinder supplier does more than just make parts today. They act as partners, helping with design, offering custom options, giving support after sales, and suggesting ways to prevent breakdowns.

Picking the right supplier means checking if they deliver strong products. They should test cylinders with methods like pressure checks and long-use tests. Suppliers must also offer solutions that fit perfectly with your machines.

Emerging Trends in Hydraulic Cylinder Technology

Customization and Application-Specific Designs

A big change in the Hydraulic Cylinders’ future is custom designs. Tailored hydraulic cylinders help machines work better and last longer. They fit specific needs in fields like farming or mining, cutting downtime from parts that don’t match. Yantai Shining Hydraulic Technology CO.,LTD provides these custom solutions, built to match client needs exactly.

Smart Hydraulic Cylinders and Integration with Digital Systems

Smart tech is changing old-school hydraulics. Smart hydraulic cylinders have sensors that track things like stroke length, pressure, temperature, and wear in real time. This helps predict when maintenance is needed, reducing sudden breakdowns.

With IoT sensors, these systems allow constant monitoring of cylinder performance. This boosts reliability and safety in critical uses, like construction cranes or automated parking lifts.

Sustainability and Eco-Friendly Solutions in Hydraulic Cylinders’ Future

Green concerns are shaping the Hydraulic Cylinders’ future. Using biodegradable fluids and recyclable materials is key. These steps cut energy use during work.

Making eco-friendly cylinders means using sustainable materials in production. Less fluid leakage also lowers harm to the environment over time.

Enhancing Performance and Efficiency Through Innovation

Efficiency is a top goal for industries using hydraulics. New tools, like proportional directional valves, give exact control over fluid flow. This balances speed and power. A proportional valve adjusts its position with a PWM controller. This setup ensures smooth control of cylinder speed.

These upgrades lead to faster work cycles for presses or smoother motion in scissor lifts used in buildings.

Customization and Modular Design in Product Development

Modular designs let makers combine standard parts in different ways quickly. This cuts wait times and allows easy upgrades or fixes later. Every business has unique needs, so makers focus on custom solutions to ensure cylinders work perfectly with your machines.

Modular systems also simplify repairs. You can replace single parts instead of the whole cylinder.

Essential Skills for Hydraulic Cylinder Professionals in 2025

Advanced Knowledge of Fluid Mechanics and System Design

Workers need strong knowledge of how fluids move to build systems that handle pressure well. They must understand how fluid thickness changes with heat or cold. This prevents failures from cavitation or oxidation. Extreme temperatures can weaken or stop cylinders, leading to costly repairs.

Understanding IoT and Smart Technologies in Hydraulic Applications

As smart hydraulics grow, workers must know how sensors work with control units through IoT systems. Skills in setting up these tools are vital for spotting issues early, like pressure drops or seal wear, before they become big problems.

Sustainable Engineering Practices for a Greener Future

Future workers need skills in building green systems. This includes using biodegradable fluids or recyclable metals. They should also know energy-saving designs, like circuits that reuse extra pressure in closed systems.

Proficiency in CAD Tools and Simulation Software

Using 3D modeling tools, engineers can test cylinder designs under real-world stress before building them. Simulation software shows how materials hold up under loads. This helps avoid early wear or failure during use.

Staying Ahead in the Evolving Hydraulic Cylinder Industry

Investing in Continuous Learning and Technical Certifications

To keep up with new tech like smart hydraulics or modular designs, workers must keep learning. Certifications in areas like advanced seals or valve tuning help them stay ready for new systems powered by AI tools.

Building Strategic Partnerships with Leading Hydraulic Cylinder Suppliers

Working with trusted suppliers like Yantai Shining Hydraulic Technology CO.,LTD ensures access to well-made solutions. They meet tough industry rules while offering custom options, like adjusting piston rod length or adding coatings to resist rust.

Their products include high-quality cylinders for farming, mining, scissor lifts, and underground car lifts. All are backed by strong quality checks.

Adapting to Market Shifts Through Agile Business Models

Companies need flexible plans to handle market changes, like material shortages or new green rules. This means improving supply chains and building production that handles both large orders and custom designs well.

Leveraging Data Analytics for Predictive Maintenance and Optimization

With sensors now common in cylinders, businesses can gather data all the time. This helps spot wear patterns or weak points early. Acting on these insights prevents small issues from becoming big, costly failures, saving time and improving safety.

FAQ Section

What are smart hydraulic cylinders?

Smart hydraulic cylinders have sensors that monitor things like stroke length, temperature, and pressure. These feed into digital systems for predictive maintenance, helping avoid unexpected breakdowns.

How does customization improve cylinder performance?

Custom cylinders are made to fit your machines perfectly. This reduces breakdowns from poor fit or wrong force, boosting efficiency. A custom cylinder is built exactly for your business needs.

Why is sustainability important in future hydraulic designs?

Green designs cut environmental harm with biodegradable fluids and recyclable materials. They also improve efficiency by reducing leaks or energy use. Using sustainable materials in production is key.

What causes overheating in hydraulic cylinders?

Overheating can come from low fluid, dirty oil clogging filters, air leaks, blocked heat exchangers, or poor flow control. Finding the cause fast prevents serious damage.

What role does Yantai Shining Hydraulic Technology CO.,LTD play?

Yantai Shining offers custom solutions, like durable cylinders for farming or mining. They provide full support, from design to after-sales help. Shining Hydraulic is located in Yantai Economic and Technological Development Zone—the Yantai Area of Shandong Free Trade Zone.

For more details on our custom solutions—from scissor lift actuators to mining-grade piston assemblies—reach out to Yantai Shining Hydraulic Technology CO.,LTD today! Let us help you shape your operations with top-notch hydraulic engineering expertise.