Key Objectives of Hydraulic Cylinder Pressure Testing

Importance of Pressure Integrity in Hydraulic Systems

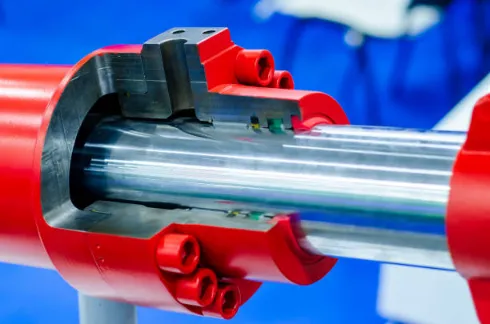

Hydraulic cylinders work under big internal pressures. Any weakness in their pressure strength can cause major problems. Making sure a cylinder can hold and handle pressure is key for machine safety and smooth running.

Hydraulic cylinders act as quiet helpers in today’s industries. They deliver strong force with good control in many machine tasks and jobs. Their skill to turn fluid power into steady straight motion relies on a tight, solid inside setup without leaks.

Testing for pressure strength does several things:

- It stops big equipment breakdowns.

- It keeps performance steady when loaded.

- It spots early wear signs such as seal wear or tiny cracks.

Typical Scenarios Requiring Pressure Testing

Many work situations need hydraulic cylinder pressure testing. Right after making them, to check quality. In regular upkeep, especially for busy factory machines. If force or speed drops fast, hinting at inside leaks or piston pump issues.

Preparing for a Reliable Hydraulic Cylinder Test

Equipment and Setup Requirements

Good hydraulic cylinder tests need the right tools and setup control. Pick checked pressure gauges. Digital ones give clearer readings. Use a strong test stand to cut down shakes. The hydraulic fluid choice counts. It has to fit system rules and stay steady in heat. Secure cylinders tight to stop shifts when pressure builds.

Safety Protocols Before Initiating the Test

Pressure testing brings dangers. So follow firm safety steps. Always release system pressure first before hooking up or unhooking the test gear. Look over all hose parts, joins, and seals for leaks or soft spots. Workers must use safety gear like face guards, hand covers, and tough clothes for pressure.

Step-by-Step Procedure for Hydraulic Cylinder Pressure Testing

Initial Inspection and Pre-Test Checks

Before adding pressure, do a full eye check. Search for outer wear, breaks, rust, or bent spots. Make sure the rod stays straight and lines up well with the cylinder body. Verify the piston pump runs right. A weak pump will mess up test outcomes.

Conducting the Static Pressure Test

This part checks if the cylinder holds pressure for a while:

- Slowly build pressure in the cylinder with a managed supply.

- Watch pressure levels for a set time, say 10 to 15 minutes.

- A pressure fall inside without outside leaks often means inside leaks or bad seals.

Bad or hurt seals lead to inside leaks. This causes uneven pressure and motion. It results in shaking.

Dynamic Testing Under Simulated Load Conditions

Dynamic testing copies real job settings:

- Run the cylinder at work speeds and pressure levels.

- Watch how smooth the rod stretches out and pulls back.

- Hesitation, odd stroke length, or shaking might point to barrel bends or bubble effects.

Hydraulic cylinder chatter shows as quick, repeating motion or shake of the cylinder. It makes noise and hurts even system work.

Diagnosing Common Issues Detected During Testing

Internal Leakage and Seal Failures

If static pressure falls slowly with no seen fluid loss. Think of inside flow past piston seals or valves. This usually cuts force output and control of the mover. These signal early wear like seal breakdown or tiny cracks.

Barrel or Rod Damage Under High Pressure Loads

With heavy loads, body harm shows up. Barrel swelling, rod scratches, or metal tiredness can appear. Cylinders with bends should not go back to work without more checks.

Enhancing Long-Term Reliability Through Regular Testing Practices

Recommended Testing Intervals Based on Application Type

How often to test depends on the job setting:

| Application Type | Recommended Testing Interval |

| Mobile Equipment | Every 6–12 months |

| Stationary Industrial | Every 12–18 months |

| Harsh Environments | Every 3–6 months |

Things in the surroundings that speed up wear, like dirt or wild heat, call for checks more often.

Integrating Testing into Preventive Maintenance Programs

Regular tests let places find problems early before they grow. Keep track of test info to guess part life. Plan seal swaps before leaks start. Skip big stoppages from surprise cylinder breaks.

Advancements in Test Equipment and Methodologies

Automation Trends in Cylinder Testing Systems

New systems use more auto features. Digital tools watch flow speeds and pressures live. Auto run setups do steady stress checks for lasting strength.

Role of Sensor Technology in Leak Detection

Better sensor gear boosts problem finding. Flow watchers spot tiny leaks eyes miss. Pressure changers give detailed info on loss speeds and reaction lines.

Considerations for Different Cylinder Types During Testing

Telescopic, Tie-Rod, and Welded Cylinder Variants

Each kind needs its own test ways:

| Cylinder Type | Special Considerations |

| Telescopic | Multi-stage seal integrity |

| Tie-Rod | Bolt torque verification |

| Welded | Structural weld inspection under pressure |

Custom Cylinders Used in Specialized Machinery

Special made cylinders need custom test plans. Load shapes must match real work stresses. Makers should help set test limits and read results.

Industry Insights from Hydraulic Component Manufacturers

Engineering Perspectives on Cylinder Durability

Cylinder lasting power depends on build and stuff. Picking materials to boost pressure handling is key in tough jobs. Cutting inside rub raises work and life.

The Role of Shining Hydraulic in Supporting Equipment Reliability

At Yantai Shining Hydraulic Technology CO.,LTD, we don’t fix hydraulic cylinders. We focus on finding top-notch swaps that fit your gear’s exact needs. They work with OEMs to match and keep system strength. For folks with repeat troubles or wrecked cylinders past fixing, Shining Hydraulic gives solid swaps made for certain jobs.

Best Practices for Maintaining Cylinder Performance Post-Test

Documentation and Traceability of Test Results

Hold full notes on each test. Time-stamped facts help spot future issues quick. Graphs of work trends help plan life cycles.

Recommendations for Storage, Handling, and Reinstallation After Testing

Care after tests matters a lot. Keep cylinders upright when you can to guard seals. Stop dirt in storage with clean covers. In putting back, check right tightness on holds and line up with links.

Evolving Standards and Compliance Requirements in Hydraulic Testing

Overview of Relevant Industry Guidelines

Hydraulic testing follows rules like:

| Standard Body | Focus Area |

| ISO 10100 | Test methods for hydraulic cylinders |

| OSHA/EN norms | Operator safety protocols |

Local rules might also shape okay fluid kinds or setup controls.

How Manufacturers Like Shining Hydraulic Align with Evolving Standards

Sticking to certs for better work lets Shining Hydraulic stay in line worldwide. They add user thoughts to product test steps. This mixes new ideas with trust.

FAQ

Q: What is static vs dynamic pressure testing in hydraulic cylinders?

Static pressure testing checks whether a cylinder can hold pressure over time without loss, mainly to detect internal leakage. Dynamic pressure testing evaluates performance during movement, simulating real operating conditions to identify issues like chatter, cavitation, or uneven motion.

Q: How can internal leaks be detected if there’s no visible fluid?

Internal leaks are identified by gradual pressure drop during static testing or reduced force and inconsistent motion during dynamic testing, even when no external leakage is present.

Q: How often should industrial cylinders undergo pressure tests?

In general, every 6–12 months for mobile equipment, 12–18 months for stationary systems, and more frequently in harsh or high-cycle conditions.

Q: What’s the role of a piston pump in a hydraulic cylinder test?

The piston pump supplies stable and sufficient pressure during testing.

Q: When should a hydraulic cylinder be replaced instead of repaired?

Replacement is recommended when testing reveals structural deformation, severe barrel or rod damage, recurring seal failures, or micro-cracks that compromise long-term pressure integrity and safety.